Advanced welding techniques are transforming car manufacturing with increased efficiency, reducing production and repair times while enhancing quality and customer satisfaction. These methods also enable complex vehicle designs, improved safety features, and longer-lasting repairs for luxury and everyday cars.

Advanced welding techniques are transforming the automotive industry, revolutionizing car manufacturing and design. From enhancing efficiency on assembly lines to unlocking complex structural possibilities, modern welding methods offer unprecedented precision and strength. These innovations directly translate into safer, more durable vehicles with improved performance and reduced weight.

This article explores how advanced welding is a game-changer for cars, impacting everything from production to overall vehicle quality.

- Enhancing Car Manufacturing Efficiency with Advanced Welding

- Unlocking Design Possibilities: Complex Joints and Shapes

- Improved Safety and Durability: The Benefits of Modern Welding Techniques

Enhancing Car Manufacturing Efficiency with Advanced Welding

Advanced welding techniques are transforming car manufacturing by significantly enhancing efficiency. These innovative methods allow for faster and more precise connections between metal parts, reducing production time and waste. Traditional welding practices often involve manual labor, which is time-consuming and prone to human error. Advanced techniques, however, leverage automation and specialized equipment to achieve consistent, high-quality welds.

This improved efficiency ripples through the entire manufacturing process, benefiting collision repair and paintless dent repair centers as well. By incorporating advanced welding into their operations, these facilities can offer faster turnaround times and higher quality repairs, thereby increasing customer satisfaction and maintaining competitive edge in the market.

Unlocking Design Possibilities: Complex Joints and Shapes

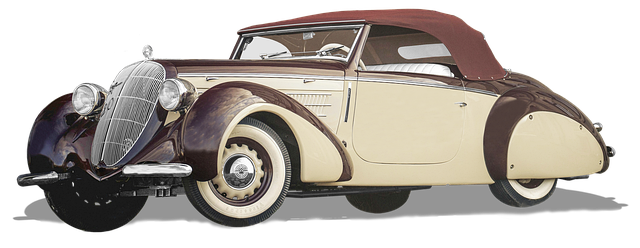

Advanced welding techniques are transforming the automotive industry by unlocking unprecedented design possibilities. With their precision and versatility, these techniques allow for the creation of complex joints and intricate shapes that were once considered impossible or impractical to achieve with traditional methods. This newfound freedom in car design translates directly into more lightweight, aerodynamic, and fuel-efficient vehicles—a significant leap forward in an era where sustainability is paramount.

For collision repair centers and car body restoration experts, advanced welding techniques also offer refined solutions for repairs and refinements. By enabling tighter tolerances and seamless fusion, these methods result in stronger, more durable bonds, ensuring that restored cars not only look as good as new but also perform at their optimal levels. This combination of enhanced aesthetics and structural integrity is revolutionizing the way we think about car dent repair and overall vehicle maintenance.

Improved Safety and Durability: The Benefits of Modern Welding Techniques

Modern welding techniques have brought about significant improvements in both safety and durability within the automotive industry. The traditional methods often left weak points and potential failure zones in car structures, especially during complex repairs or alterations. However, advanced welding techniques such as laser welding, robot-assisted arc welding, and TIG (Titanium Gas) welding offer superior precision and control, ensuring that each joint is seamlessly fused.

These modern approaches not only enhance structural integrity but also contribute to enhanced safety features in vehicles. For instance, precise welding allows for the integration of advanced safety systems, like high-strength crumple zones and intricate frame designs, which can better protect occupants during accidents. Moreover, improved durability means reduced maintenance needs and longer lifespans for luxury vehicle repairs, automotive restoration projects, and even everyday car body repairs, ultimately saving time and money for car owners.

Advanced welding techniques are truly revolutionizing car manufacturing, offering unprecedented efficiency gains, enhanced design flexibility, and superior safety features. By leveraging complex joint configurations and innovative materials, modern welding methods ensure cars are built stronger, lighter, and more reliably than ever before. These game-changing practices continue to push the boundaries of automotive engineering, setting the stage for even more remarkable vehicle advancements in the future.